What is Acid Insoluble Ash Content Testing?

Acid Insoluble Ash Content Testing is an analytical procedure used to determine the amount of siliceous matter—mainly sand, silica, and other mineral impurities—present in a sample that remains insoluble after treatment with hydrochloric acid. It is a refinement of the total ash test, where the ash obtained by incinerating the material is further boiled with dilute hydrochloric acid to dissolve acid-soluble salts, leaving only the acid-insoluble fraction.

This residue, composed primarily of silicates and siliceous earth contaminants, is filtered, ignited, and weighed. The method is widely applied in the quality control of pharmaceuticals, herbal drugs, and food products, as excessive acid-insoluble ash indicates adulteration, contamination, or poor handling during processing. Thus, it serves as a critical parameter for assessing purity, ensuring compliance with pharmacopeial standards, and safeguarding product safety.

Acid Insoluble Ash Content Testing Procedure

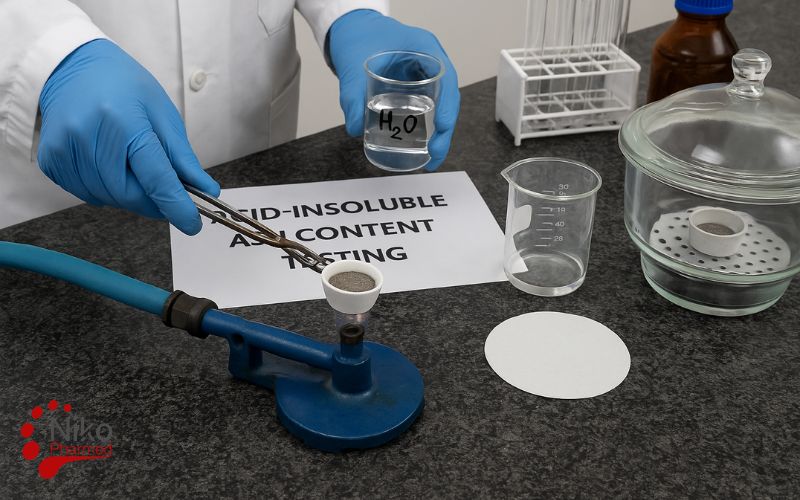

Acid-insoluble ash content testing quantifies the siliceous (sand/silica) fraction of total ash that resists dissolution in mineral acid and is performed as follows in a controlled, gravimetric workflow: a representative, finely pulverized test portion (typically 2–5 g, accurately weighed to 0.1 mg) is incinerated in a pre-ignited, tarred silica or platinum crucible by gradual charring over a low flame and then ashed in a muffle furnace at 525–600 °C until a light, carbon-free residue of constant mass is obtained.

After cooling in a desiccator, the ash is moistened with a few drops of distilled water, treated with 25–50 mL of dilute hydrochloric acid (e.g., 2 M or 10% w/v), covered, and gently boiled for about 5 min to dissolve acid-soluble salts (carbonates, phosphates, chlorides). The hot mixture is filtered through a pre-weighed, ashless filter paper (or a sintered-glass crucible, porosity G3–G4); the crucible and vessel are rinsed thoroughly, and the residue is washed with hot water until washings are free of chloride (tested with AgNO₃).

The filter and residue are dried, then ignited in the original tarred crucible at 525–600 °C to constant mass, cooled in a desiccator, and weighed; if a sintered crucible is used, it is dried at 105–120 °C or ignited per method and reweighed. The acid-insoluble ash (%) is calculated as: %AIA= (mresidue−mblank /msample)×100%, where a parallel blank (acid and filtration without sample) corrects for reagent or filter contribution when required.

Critical controls include slow initial charring to avoid spattering, sufficient ashing time to remove carbon (repeat ignite–cool–weigh cycles to constant mass), maintaining acid strength and boil time to ensure complete dissolution of acid-soluble ash, quantitative transfer and washing, and protection from atmospheric moisture by cooling in a desiccator. The result specifically reflects exogenous mineral contamination (silica/silicates) rather than intrinsic mineral content and is a key purity attribute in pharmacopeial, herbal, and food matrices.

Nikopharmed Acid-Insoluble Ash Testing laboratory

Global Recognition

ISO/IEC 17025-certified and ILAC-accredited, Nikoopharmed delivers internationally recognized Acid-Insoluble Ash (AIA) analysis for pharmaceuticals, herbal products, and food materials.

Technical Excellence

Using pharmacopeial gravimetric methods (USP, EP, IP), we provide:

Quantification of acid-insoluble ash (silica, sand, adulterants)

Purity assessments of raw and finished products

Routine quality control and regulatory compliance testing

Regulatory-Ready Reports

Our traceable, GLP-compliant reports support pharmacopeial standards, consumer product safety, and global regulatory submissions.

Confidential & Cost-Effective

21 CFR Part 11-compliant systems ensure secure, reliable data. Flexible study designs and competitive pricing serve pharmaceutical, herbal, and food industries.

To request testing or a complimentary consultation contact Nikopharmad

Nikopharmed; Your Trusted Partner

Nikoopharmed delivers precise, defensible results that safeguard quality, protect health, and streamline approvals. Our chemical testing portfolio covers heavy metals, moisture, ash and acid-insoluble ash content testing, and more.