What is Viscosity Testing?

Viscosity testing is a critical measurement used to determine the resistance of a fluid to flow, which is an essential property in many industrial and scientific applications. It quantifies the internal friction between fluid layers as they move relative to each other, providing insight into the fluid’s flow behavior under various conditions.

The testing is conducted using standardized methods, such as the ASTM D445 or ISO 3104, which specify the procedures for measuring kinematic and dynamic viscosity using viscometers or rheometers. These methods involve placing a sample of the fluid in a controlled apparatus and measuring its flow rate or the force required to induce flow under specified temperature and shear conditions.

The results are typically expressed in units of centipoise (cP) or pascal-seconds (Pa·s) for dynamic viscosity and centistokes (cSt) for kinematic viscosity. Viscosity testing is crucial in sectors such as lubricants, food processing, and pharmaceuticals, where the fluid’s flow characteristics can significantly impact product performance and processing efficiency. In many QA/QC programmes, viscosity measurements are interpreted alongside Density Testing and Conductivity Testing to understand how formulation changes affect both flow behaviour and bulk physical properties

Viscosity Testing Procedure

The procedure for viscosity testing follows a standardized approach to accurately measure a fluid’s resistance to flow under controlled conditions. According to standards such as ASTM D445 or ISO 3104, the viscosity testing process typically involves the following steps:

Sample Preparation

The fluid sample is prepared by ensuring it is homogeneous and free from any air bubbles or contaminants that may affect the measurement. The sample’s temperature is crucial, as viscosity is highly temperature-dependent, and specific test methods require the fluid to be at a standard temperature (usually 40°C or 100°C for petroleum products).

For liquid, semi-solid and suspension products, viscosity testing is often scheduled in parallel with pH Testing so that flow properties can be correlated with product stability, solubility and specification limits.

Viscometer Selection

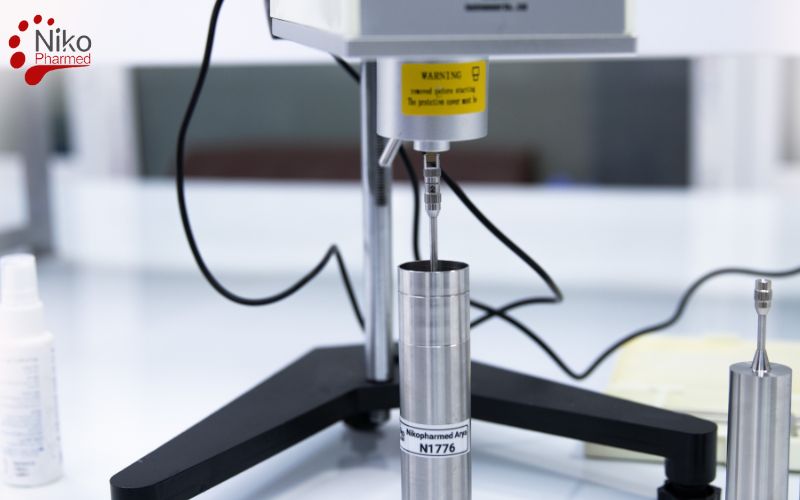

The appropriate viscometer or rheometer is selected based on the type of viscosity being measured (dynamic or kinematic) and the fluid’s characteristics. Common types of viscometers include capillary viscometers, rotational viscometers, and falling ball viscometers. The device must be calibrated according to the standards to ensure accuracy.

Testing Procedure

- For kinematic viscosity, a known volume of the fluid is placed in a capillary viscometer, and the time it takes for the fluid to flow between two marked points under the influence of gravity is measured. The kinematic viscosity is then calculated using the time and the specific dimensions of the viscometer.

- For dynamic viscosity, the fluid sample is subjected to shear stress, and the resistance to flow is measured. Rotational viscometers are commonly used, where the sample is placed between two rotating surfaces, and the torque required to maintain a constant rotational speed is recorded. The dynamic viscosity is calculated from the relationship between the applied torque and the rate of shear.

Temperature Control

Since viscosity is temperature-dependent, maintaining a consistent temperature during testing is essential. Many standards recommend testing at multiple temperatures, and temperature-controlled baths or ovens are used to ensure the sample remains at the specified temperature throughout the procedure.

Calculation and Reporting

The viscosity is calculated based on the measurements taken during the test. The final result is expressed in the appropriate units (centipoise or pascal-seconds for dynamic viscosity, centistokes for kinematic viscosity). The results may be compared to reference values or used for further analysis, depending on the specific requirements of the industry or application.

Data Interpretation

The viscosity values are analyzed in conjunction with other properties of the fluid to assess its suitability for its intended application. In some cases, the data may be used to determine the fluid’s performance under varying operational conditions or to establish quality control criteria for product consistency.

By adhering to these standardized procedures, viscosity testing ensures reliable, repeatable results, which are essential for the formulation, quality control, and performance optimization of fluids across a wide range of industries.

Nikopharmad Viscosity Testing Laboratory

Accreditation and Global Recognition

At Nikopharmad, our Viscosity Testing services are supported by ISO/IEC 17025 certification and ILAC accreditation, ensuring full compliance with internationally recognized standards of analytical quality and technical competence. These prestigious credentials confirm that our viscosity testing data meet the highest global regulatory requirements, accepted by health authorities and regulatory bodies worldwide.

Technical Excellence and Validated Infrastructure

Our state-of-the-art laboratory is equipped with advanced, precision-controlled instruments, including calibrated viscometers and rheometers. We follow validated methodologies, such as ASTM D445, ISO 3104, and other industry standards, to deliver reliable and reproducible viscosity measurements. With precise temperature control and standardized calibration protocols, our testing procedures ensure accurate viscosity results for a wide range of samples, from pharmaceuticals to industrial fluids.

Regulatory-Ready Reporting and Timely Results

In the fast-paced regulatory environment, timely and reliable results are essential. Nikopharmad ensures rapid delivery of viscosity testing results without compromising accuracy. Our streamlined process and comprehensive quality assurance protocols provide complete documentation with traceable raw data, statistical analysis, and regulatory submission-ready final reports. Our testing results are suitable for FDA, EMA, and other global regulatory filings, ensuring your data is aligned with international standards.

Confidentiality and Data Integrity

At Nikopharmad, client confidentiality and data security are paramount. All viscosity testing is conducted under strict confidentiality agreements and supported by 21 CFR Part 11-compliant electronic data systems. Our protocols ensure the integrity of all test data, with a complete audit trail and ethical handling of test materials. We uphold the highest standards of data protection, ensuring your sensitive information remains secure throughout the testing process.

Competitive Pricing with Uncompromised Quality

We understand the importance of cost-effective testing in product development. Nikopharmad offers competitive pricing for viscosity testing services, tailored to meet the needs of startups, SMEs, and multinational companies. Our pricing model is designed to support your regulatory goals, helping to accelerate product approval timelines while maintaining the highest standards of accuracy and compliance.

To request testing or a complimentary consultation contact Nikopharmad

Partner with Nikopharmad for Expert Viscosity Testing

By choosing Nikopharmad for your viscosity testing needs, you align with a globally accredited laboratory committed to scientific excellence, regulatory compliance, and client confidentiality. Whether you are testing industrial lubricants, pharmaceutical formulations, food products, or other fluids, our viscosity testing expertise ensures fast, reliable, and internationally recognized results—making us the ideal partner for developers seeking efficient and compliant market access.